Equipment and Ideas

Here is where I will post various ideas, innovation or resources for useful equipment, or books.

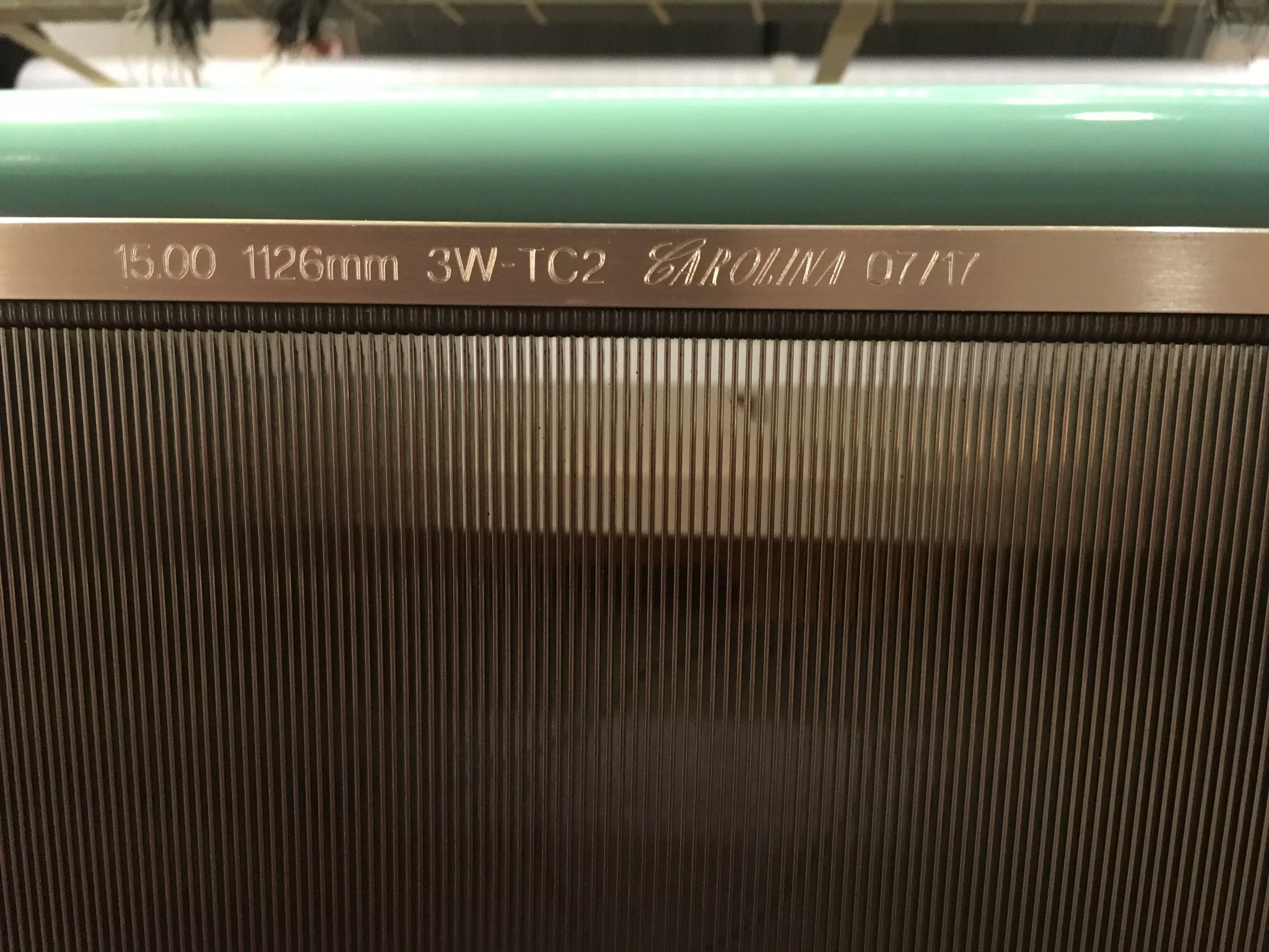

Reeds for the TC2 made in America!

I have found a good source for reeds:

Carolina Loom Reeds.

They have the specs for the TC2. The cost is very reasonable. I got one reasonably quickly.

Warping

Everything you might need to know or try, to find your best set of procedures for warping the TC-2. There are 3 books in this series. I own them all. They are worth every penny. I refer to these 2 for winding and warping. The warping book seems to be only available for download currently...

Warping Your Loom and Tying on New Warps

I got mine here:

https://peggyosterkamp.com/downloads/warping-loom-tying-warps-4th-edition/

You can go to Peggy's website or Amazon

https://peggyosterkamp.com/weaving-books-dvd/

Winding a Warp and Using a Paddle

A spring and an S hook

I'm not the only one enamored with S hooks. They are my little darlings. Although you may thread only once or twice, I have found this little system to be crazy awesome. The spring holds threads you have just threaded to the side while you reach past the heddles to the lease sticks. The S hook holds groups of threads to the side in slip knotted bundles so they don't get rubbed back into the heddles when you reach forward.

One TC-2 user Camilla in Norway immediately adapted this idea and sewed the spring onto an elastic band with magnetic snaps.

made by Glimakra

Temples

I resisted for years....and then I tried one for more than a few picks. Once I got the hang of it, I found that my weaving was better and my selvedges were better. The beater on the TC-2 will get scratched up if you use a temple where the prongs are pointed down- so use one like this. We've also experimented with alligator clips, cords and bagged weights.

Shuttles

I do use a variety of shuttles. However, the bulk of my work is with end feed shuttles. This is not a requirement for working on the TC-2 - it is a preference. I use this image a lot - partially, I will admit because I often hear exclamations and it makes me feel like a badass. I also refer to this image as "The view from crazy town"- but in fact, it should be called the "View from Orderville".

It represents the way I like to operate. Temple in place, the shuttles lined up, threads pulled just so thru the tension devices, 2 tables at my hips a notebook with pen and tester. The beautiful little shuttles are my jewels. They are used almost exclusively for supplementary wefts- even though I could use anything. The end feed shuttles I use are from schacht- I prefer the 12 inch ones.

The smaller shuttles are Bluster bay from a variety of vendors. The shed on the TC2 is a bit lower than other looms- so those bigger boxy shuttles don't fly thru with ease.

Electric Bobbin Winder

This is the bobbin winder I have. There are several excellent ones on the market. I don't think I own a hand crank one, those are fine too. I just have too many bobbins to wind to enjoy using those.

Lighting

I use 3 forms of light when I weave. I have a swing arm lamp clamped to the loom frame, overhead lights in the studio and these under-frame LED strip lights

Strip Led lights - pictured here taped on. I currently have them attached with magnetized strips.

I have a thin board (1"x3") supporting the clamp of this lamp...the metal frame at this location can get bent otherwise.

Your wheels may not look the same as these. Contact the company and discuss weight requirements.

Link here for specs I used to add mine.

Tables/Carts

These carts are from Ikea- now discontinued. The drawers are awesome. the height is perfect.

Cone Supports

plumbing fittings 1". heavy enough to keep cones from tipping. They can be located where I want. I prefer these as opposed to the board and peg type.

Raddle

hand built raddle with eye hooks spaced 1 cm apart. Rod is used to keep the raddle groups from coming out. In case you are unfamiliar, the raddle spaces the warp while winding on.

Schacht Paddle

I use this to wind my warps. This holds up to 50 yards. This isn’t my own studio set up- but is the best image I have for this wheel. Note the handy table nearby, the stool- the cool can for saving the ties.

Seine twine is my favorite for choke ties.

https://www.yarnbarn-ks.com/12_6-Cotton-Seine-Twine/productinfo/WY%2DSEINET%2D/

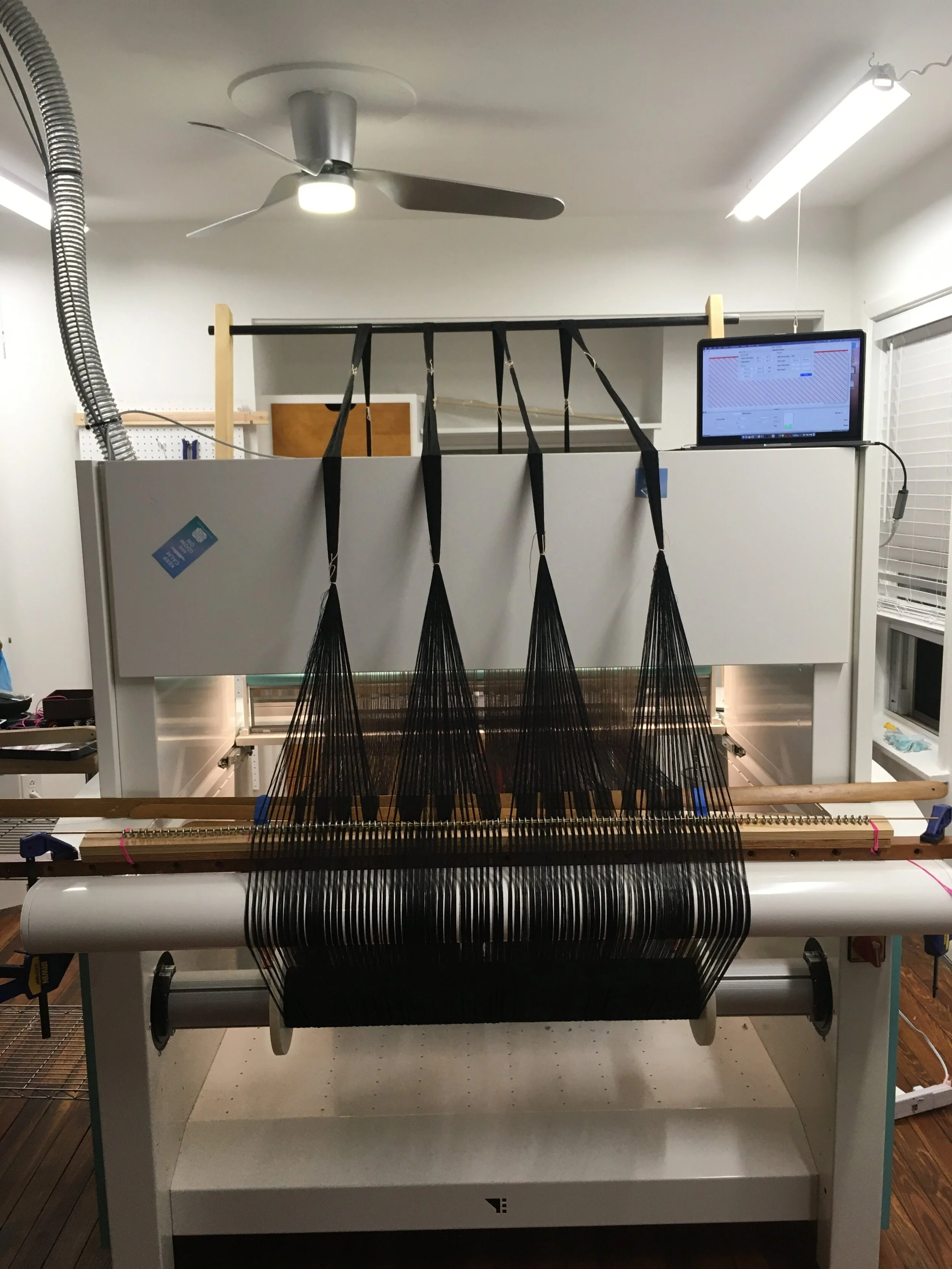

The images here are from various loom installations and the tools/methods they are using to beam their warps.